AGRUAIR - A Compressed Air Piping System

Friday, 6th December 2013

Categories:

Product Info

Compressed air is used throughout industry as an economical source of clean energy. An leaks in a compressed air system cause energy loss, which reduces efficiency and leaks can lower the air quality.

A thermoplastic piping system can offer a number of key advantages for compressed air systems. In particular, thermoplastic pippng resists corrosion, it is easy to handle and beadless welding creates a completely smooth inner bore, resulting in a minimal pressure drop across the system.

In the case external impact, the thermoplastic material will prevent cracks forming which could otherwise destroy the piping system if it were made from a more brittle material. AGRUAIR also has excellent chemical resistance - especially to compressor oils.

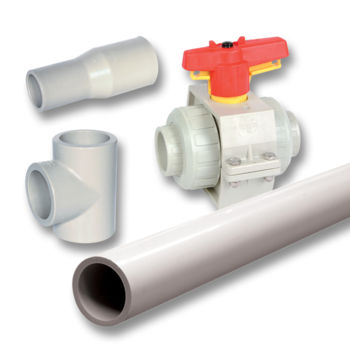

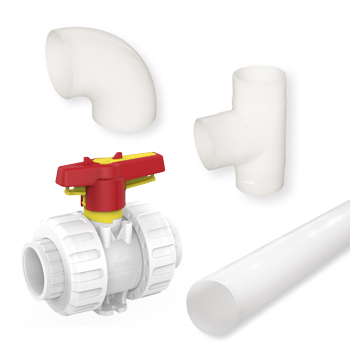

AGRUAIR piping systems are specifically designed for the transportation of compressed air in industrial environments. Manufactured from PE100 polyethylene, this high quality piping system has a wide range of sizes and component parts to satisfy the most demanding of applications.

These systems are joined by socket fusion welding by hand-held, bench mounted tools, or by electro-fusion welding. The joints will remain leak-proof for the lifetime of the installation.

This piping system can also be connected to other materials and equipment using special fittings complete with metal male or female threaded parts that can be used as transition fittings.

This range includes pipes, valves and fittings in diameters from 20mm to 110mm. AGRUAIR is designed for a maximum operating pressure of 16 Bar (PN16) (this includes a safety factor of 2.0 - the required factor for pressurised gaseous media).

A thermoplastic piping system can offer a number of key advantages for compressed air systems. In particular, thermoplastic pippng resists corrosion, it is easy to handle and beadless welding creates a completely smooth inner bore, resulting in a minimal pressure drop across the system.

In the case external impact, the thermoplastic material will prevent cracks forming which could otherwise destroy the piping system if it were made from a more brittle material. AGRUAIR also has excellent chemical resistance - especially to compressor oils.

AGRUAIR piping systems are specifically designed for the transportation of compressed air in industrial environments. Manufactured from PE100 polyethylene, this high quality piping system has a wide range of sizes and component parts to satisfy the most demanding of applications.

These systems are joined by socket fusion welding by hand-held, bench mounted tools, or by electro-fusion welding. The joints will remain leak-proof for the lifetime of the installation.

This piping system can also be connected to other materials and equipment using special fittings complete with metal male or female threaded parts that can be used as transition fittings.

This range includes pipes, valves and fittings in diameters from 20mm to 110mm. AGRUAIR is designed for a maximum operating pressure of 16 Bar (PN16) (this includes a safety factor of 2.0 - the required factor for pressurised gaseous media).

Categories

Archive

Tags

kessel

ips flow systems

agru

backwater protection

drainage

exhibition

rm pressfit

ips

blazemaster

pvdf

spears manufacturing

ips dublin

cpvc fire protection

flameguard

drainage by design

construction week

polyethylene pipe

aqualift f

excel london

installation tools

uk construction week

nec

lifting station

floor drains

ecolift xl

aespres

pe100-rc

pumping station

aqualift f xxl

alzheimer's society

uk build 2018

building information management; bim

grease seperator

flood protection

fluid handling solutions

inoxpres

ecobuild

webinar

pvc

praher

demo van

staufix

business development manager

uk build

new staufix

polypropylene pipe

pump centre conference

fire suppression

mupro

drainage protection; staufix

Get In Touch

- sales@ipsflowsystems.com

- 0191 521 3111

- Seaham Grange Industrial Estate, Seaham, Durham, SR7 0PT,