Guide to Double Containment Pipework

What Is double Containment

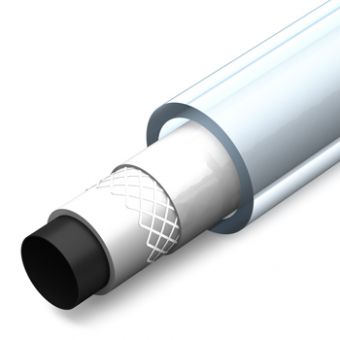

Double Containment is a pipe within a pipe, where the inner pipe is used to transport hazardous media, or media that must not come into contact with lifeforms, and the outer pipe is used to catch any leak from the inner pipe if a leak was to occur, and transport that leak to a safe bunded area.

The way that leak is then identified will be answered later in this guide.

There are a number of systems available on the market from different manufacturers, both in flexible and rigid systems, as well as materials. In the following pages we will be dealing with systems supplied by IPS Flow Systems Ltd only, and describing various ways and means of installation as well as minimising the amount of materials needed to repair a system if a leak was to occur.

Systems.

Systems available are as follows; Flexible hose system; Rigid imperial solvent weld PVCU and PVCC systems, and Metric PP, PE and PVDF Butt Fusion systems.

Each of these systems have their own merits, and come into their own, depending on the environment they are being installed in, and the media they are transporting.

The simplest method is the hose system, but this is normally a point "A" to "B" system, whereas the rest have more available direction change fittings, but require more installation. In the pages below we will try and discuss the differences, and what can be achieved in each system.

Zoning Fittings

Zoning fittings are crucial in long run installations. Often overlooked because of extra cost, clients should look to the future to safe guard themselves against costly repairs, as zoning fittings in conjunction with a leak detection fitting, will save the customer from replacing ALL of the installation, depending on how many Zones the client wishes to install.

For example, in a 100m run of pipework, the client may wish to have 4 zones of 25m. This would require 3 zone fittings and 4 leak detection fittings. These extra costs will increase the initial installation cost, but the saving would come into its own if a leak occurred as only 25m of piping would be required, along with a few fittings to install the new pipework... no need to replace the full 100m.

Leak Detection

Once again, leak detection is often overlooked or not included because of cost. These are crucial to the system working effectively, as if you don't include them then you will never know you have a leak.

Usually supplied as visual only detection from IPS, they can be modified by the client for mechanical or electrical detection.